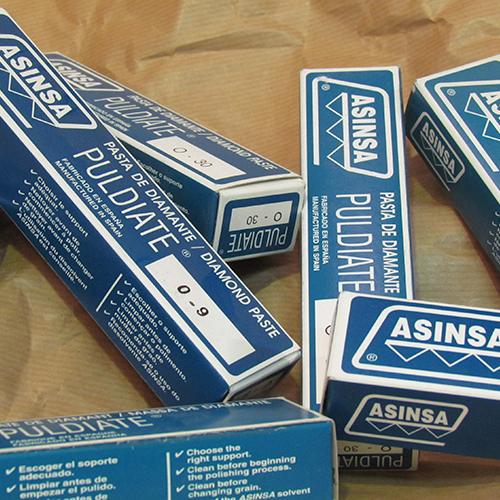

PULDIATE polishing paste

The constant evolution of modern industry demands ever-improving surface finishes. Among the range of abrasives available, Diamond is the only one that provides the ultimate solution for achieving the desired finish qualities.

Its great hardness and durability maintain a constant aggressiveness on every cutting particle. Therefore, diamond remains irreplaceable for polishing all types of materials.

ASINSA produces “PULDIATE” Diamond Paste, which contains rigorously selected diamond grains, resulting in a product with absolute guarantee. Its optimal concentration and uniform particle dispersion allow for unsurpassed quality finishes with minimal time and effort.

“PULDIATE” pastes cover a wide range of grain sizes, from 90 microns for the coarsest, to ¼ micron for the finest.

They are manufactured in two different types: Type W, water-soluble, and Type O, oil-soluble.

Type W (in water) is used with non-greasy vehicle mixtures, such as water, alcohol, etc.

Type O (in oil) is used with mixtures of fatty vehicles such as vegetable oil, petroleum.

ASINSA supplies a special liquid for use as a solvent vehicle for both type W and type O.

RECOMMENDATIONS FOR USE

To use “PULDIATE” paste correctly, it is first necessary to choose the appropriate backing for each specific application. The shape of the surface to be polished must be taken into account, as well as the material, hardness, and degree of finish required. In general, backings with hard materials are used for coarse grain sizes, and soft ones for fine finishing grains. Before beginning the polishing process, it is essential to thoroughly clean the piece, ensuring it is free of any foreign particles that could hinder the process.

After each application with a specific grain of paste, the surface must be completely cleaned again, so that when the next (finer) paste is applied, there are no traces of the previous one.

It is necessary to mark the polishing pads and use them only for a specific type of paste.

WORKING METHOD WITH “PULDIATE” ASINSA

A small amount of paste is placed on the support or the workpiece to be polished, and polishing begins, either manually or mechanically. Due to the heat produced by friction, it thickens until it dries completely. A liquid vehicle (“PULDIATE” liquid) must then be applied to give it fluidity, allowing the polishing process to continue.