Diamond paste Puldiate

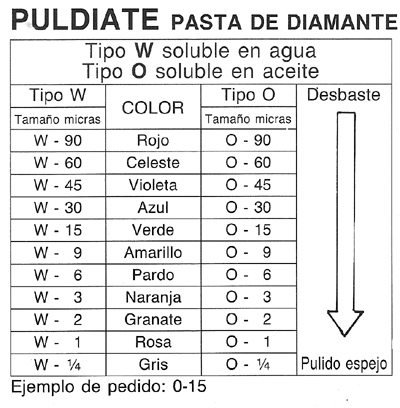

ASINSA elaborates for years the diamond paste PULDIATE that contains rigorously selected grains of diamond, obtaining a product of absolute guarantee. Its suitable concentration and the uniform dispersion of its particles, allow obtaining finishings of insuperable quality with the minimal time and effort. The PULDIATE pastes include a wide range of sizes of grain, from 90 Microns the coarsest up to 1/4 of Micron the thinnest.

They are made of two different types: Type W soluble in water and Type O soluble in oil.

The type W (in water) is in use for mixtures with non- greasy vehicle as water, alcohol, etc...

The type O (in oil) is in use for mixtures with non greasy vehicle as vegetable oil, oil, etc...

ASINSA supplies a special liquid to use as dissolvent vehicle both in type W and in type O.

Recommendations for PULDIATE's use

For the correct use of the PULDIATE paste, it is necessary firstly to choose the support adapted for every particular application. The shape of the surface to polish has to be beared in mind, as well as its material, the hardness, and the degree finishing desired In general the supports of hard material are used for coarse grains and the smooth ones for thin grains for finishing. Before beginning the polishing, it is mandatory to clean the piece thoroughly assuring that remains free of any strange particle that could alter the process. After every application with a certain grain of paste, the surface must be cleaned again completely in order that on the application of the thinner following paste, there are no remains of the previous one that were preventing obtaining a good final result. Likewise it is completely necessary to mark the polishing supports and use them only for a certain type of paste.Working method

Place a small quantity of paste in the support or in the surface to polish and start working, either manually or mechanically. Due to the heat produced by the work and the extracted material mixing with the paste, it thickens up to dry off almost completely. It is then necessary to apply to it a liquid vehicle (PULDIATE liquid) to give it fluency and to be able to continue the polishing.